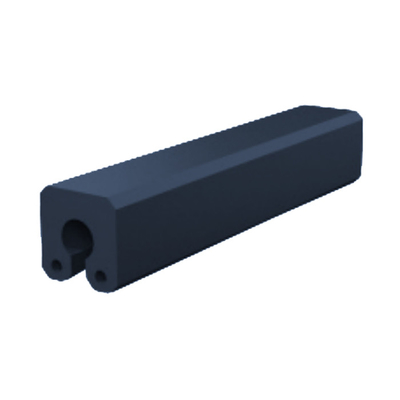

Parafango cilindrico 650×1500mm Struttura robusta Basso costo di invecchiamento Efficace

Descrizione

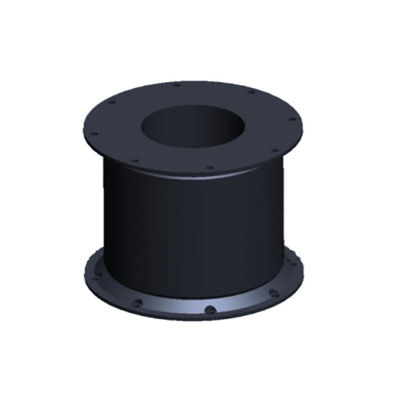

I nostri parabordi marini cilindrici sono dotati di molteplici configurazioni di montaggio per adattarsi a varie applicazioni, da porti e banchine a piattaforme offshore. Realizzati con composti di gomma ad alta resistenza, questi parabordi offrono un equilibrio tra elasticità e resistenza, adattandosi alle forze di attracco dinamiche. Le dimensioni variano da 400 mm a 1000 mm e l'installazione può essere personalizzata in base alla struttura: sospesi a catena, montati su flangia o direttamente imbullonati. Sono disponibili piastre antiusura e rivestimenti protettivi opzionali per una maggiore durata. Questi parabordi sono progettati per offrire prestazioni costanti per anni di funzionamento, riducendo la frequenza di manutenzione e i rischi operativi. La loro forma uniforme consente inoltre una facile sostituzione e intercambiabilità nelle configurazioni esistenti.

Specifiche

| Nome del prodotto |

Parabordi marini cilindrici |

| Materiale |

Gomma naturale, NBR, EPDM |

| Standard |

PIANC2002, HGT2866-2016 |

| Dimensione |

ID: 75-1000mm; OD: 150-2000mm o Personalizzato |

| Colore |

Rosso, Giallo, Blu, Nero, Bianco ecc. |

| Durezza |

55 Shore A |

| Servizio di elaborazione |

Stampaggio, Taglio |

| Resistenza alla trazione |

≥18 MPA |

| Allungamento a rottura |

≥400% |

| Caratteristica |

Rispettoso dell'ambiente |

| Applicazione |

Banchina, Porto, Molo, Barca |

| Vantaggio |

Elevata resilienza |

| Qualità |

Lunga durata |

| Funzione |

Assorbimento degli urti |

| Servizio |

Servizio personalizzato OEM ODM |

| Imballaggio |

Imballaggio interno: A. Separato, Ogni pezzo con un'etichetta di cura + Telone

B. Lotti, Ogni pezzo è imballato in una pellicola di plastica trasparente

Imballaggio esterno: Telone o pellicola di plastica

|

| Modello |

Lunghezza |

Diametro interno |

Diametro esterno |

| Cilindrico |

[mm] |

[mm] |

[mm] |

| HM-CMF150 |

Lunghezza personalizzata |

75 |

150 |

| HM-CMF200 |

100 |

200 |

| HM-CMF250 |

125 |

250 |

| HM-CMF300 |

150 |

300 |

| HM-CMF400 |

200 |

400 |

| HM-CMF500 |

250 |

500 |

| HM-CMF600 |

300 |

600 |

| HM-CMF700 |

350 |

700 |

| HM-CMF800 |

400 |

800 |

| HM-CMF900 |

450 |

900 |

| HM-CMF1000 |

500 |

1000 |

| HM-CMF1100 |

550 |

1100 |

| HM-CMF1200 |

600 |

1200 |

| HM-CMF1400 |

700 |

1400 |

| HM-CMF1600 |

800 |

1600 |

| HM-CMF700 |

850 |

1700 |

| HM-CMF800 |

900 |

1800 |

| HM-CMF1900 |

950 |

1900 |

| HM-CMF2000 |

1000 |

2000 |

Caratteristiche

Ampia gamma di dimensioni

Disponibile in diametri da Ø300mm a Ø1200mm e lunghezze fino a 3000mm, per adattarsi a vari tipi di imbarcazioni e condizioni di attracco.

Lunga durata

Costruito in gomma di alta qualità per uso marino con resistenza superiore all'invecchiamento, all'usura e al degrado ambientale.

Elevata resistenza all'abrasione

La mescola di gomma è progettata per resistere al contatto e all'attrito ripetuti delle imbarcazioni senza strappi o deformazioni.

Eccellente resistenza ai raggi UV e all'ozono

Ideale per l'esposizione prolungata all'aperto, mantenendo le proprietà meccaniche anche sotto la forte luce solare e in ambienti costieri.

Applicazioni

● Bacini di carenaggio

● Piattaforme offshore

● Operazioni nave-nave

Vantaggi

Costruzione solida, senza manutenzione

A differenza dei parabordi pneumatici o in schiuma, i nostri parabordi cilindrici in gomma piena non richiedono gonfiaggio, monitoraggio della pressione interna o manutenzione delle valvole. Una volta installati, offrono prestazioni stabili per molti anni senza l'intervento dell'operatore.

Materiali ecocompatibili e conformi

Utilizziamo materiali in gomma riciclabili e non tossici che sono conformi alle normative ambientali nelle operazioni globali di spedizione e portuali. La nostra fabbrica mantiene standard rigorosi per ridurre al minimo i rifiuti e l'inquinamento durante la produzione.

Applicabile a un'ampia gamma di tipi di imbarcazioni

I nostri parabordi sono adatti per piccole imbarcazioni, rimorchiatori, chiatte, traghetti, navi da carico e petroliere. Sono utilizzati in porti, terminal, banchine, piattaforme offshore e cantieri navali in tutto il mondo, fornendo una protezione affidabile in diversi ambienti marini.

Tempi di produzione rapidi e logistica efficiente

Manteniamo un efficiente approvvigionamento dei materiali, sistemi di inventario e cicli di produzione per garantire tempi di consegna brevi. Il nostro team logistico esperto gestisce il trasporto nazionale e internazionale con imballaggi sicuri e supporto alla documentazione.

FAQ

1. Come viene installato un parabordo cilindrico?

I parabordi possono essere montati orizzontalmente o verticalmente utilizzando catene, bulloni a U, staffe o fissati direttamente alla parete della banchina o allo scafo della nave.

2. Qual è la capacità di assorbimento di energia dei vostri parabordi?

L'assorbimento di energia varia in base alle dimensioni e al tipo; grafici delle prestazioni dettagliati sono disponibili su richiesta o nelle nostre schede tecniche.

3. I parabordi cilindrici possono essere personalizzati?

Sì, offriamo la completa personalizzazione, tra cui dimensioni, lunghezza, fori di montaggio, rinforzo interno e trattamenti superficiali.

4. I vostri parabordi sono conformi agli standard internazionali?

Sì, i nostri parabordi sono fabbricati in conformità con le linee guida ISO 17357, PIANC e altri standard globali di ingegneria marittima.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!