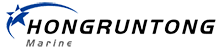

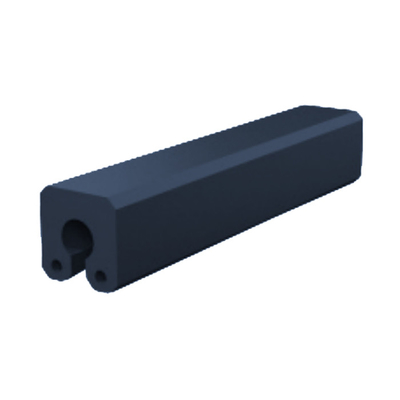

Fenders marini Alta efficienza energetica Lunga durata prestazioni stabili

Descrizione

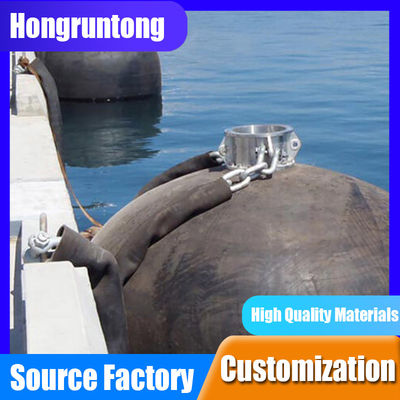

Per le operazioni di ricerca in acque profonde, i Fender forniscono una protezione vitale quando si attraccano navi sommergibili sensibili e costose.e strumenti scientifici montati esternamenteAnche piccole collisioni durante l'attracco possono causare riparazioni costose o perdita di dati.superfici non marcatrici e elevato assorbimento degli urti per garantire che gli strumenti della nave rimangano intattiSono spesso realizzati con nuclei pieni di schiuma contenuti in strati di poliuretano o gomma resistenti all'abrasione, che offrono una lunga durata di vita con una manutenzione minima.

(Caso: un istituto di ricerca marina gestisce un sommergibile da 12 persone utilizzato per studiare gli ecosistemi in acque profonde.creando condizioni instabili di attraccamentoPer proteggere il sottomarino, l'Istituto ha installato dei parafanghi galleggianti lungo il molo, che salgono e scendono con il livello dell'acqua.mantenere un contatto costante con lo scafo del sottomarino durante l'attraccoIn una missione di ritorno, onde inaspettate da una nave da carico che passava colpirono proprio mentre il sottomarino si avvicinava al molo.impedendo al sottomarino di colpire il molo di cementoIn seguito l'equipaggio ha riferito che senza i parafanghi, le serie di sonar sensibili sulla prua avrebbero potuto essere danneggiate.)

Specificità

| Materiale |

SBR, NR |

| Dimensioni disponibili |

3.3*10.6M |

| Resistenza alla trazione |

=> 18 MPA |

| Densità |

90+/-5 |

| Colore |

Nero |

| Applicazione |

Submarino, traghetto, piattaforma petrolifera e così via |

| Durezza |

40-70 Riviera A |

| L'allungamento |

=> 400 |

| Forza della lacrima |

> 400 N/cm |

| La forza di rompere |

> 310 |

|

Resistenza chimica

|

Combustibile A: nessun deterioramento |

| Olio 3: Nessun deterioramento |

| Olio lubrificante: nessun deterioramento |

| Olio da taglio: nessun deterioramento |

| HCL diluito: nessun deterioramento |

Diametro x

Distanze |

Iniziale

Interno

Pressione |

Nave

Radio |

Acqua

Rapporto |

Garantito

Energia

Assorbimento |

Reazione

Forza

presso GEA |

Casco

Pressione

presso GEA |

Deformazione

presso GEA |

| (mm x mm) |

(kPa) |

(mm) |

(%) |

(kJ) |

(kN) |

(kPa) |

(%) |

| 1500 x 6100 |

50 |

3000 |

60% |

131 |

562 |

140 |

51% |

| 80 |

186 |

754 |

188 |

| 1700 x 7200 |

50 |

4000 |

65% |

167 |

682 |

137 |

47% |

| 80 |

239 |

918 |

184 |

| 2000 x 6000 |

50 |

4000 |

70% |

135 |

544 |

131 |

41% |

| 80 |

194 |

736 |

177 |

| 2500 x 5500 |

50 |

4500 |

65% |

225 |

769 |

135 |

41% |

| 80 |

322 |

1035 |

182 |

| 2500 x 7700 |

50 |

4500 |

70% |

326 |

1016 |

136 |

41% |

| 80 |

470 |

1368 |

183 |

| 3300 x 6500 |

50 |

4500 |

75% |

307 |

887 |

127 |

35% |

| 80 |

442 |

1203 |

173 |

| 3300 x 10600 |

50 |

5000 |

65% |

1003 |

2137 |

142 |

47% |

| 80 |

1429 |

2863 |

190 |

| 4500 x 9000 |

50 |

5000 |

60% |

1439 |

2401 |

138 |

46% |

| 80 |

2059 |

3228 |

185 |

| 4500 x 12000 |

50 |

6000 |

65% |

1977 |

3198 |

141 |

46% |

| 80 |

2819 |

4277 |

189 |

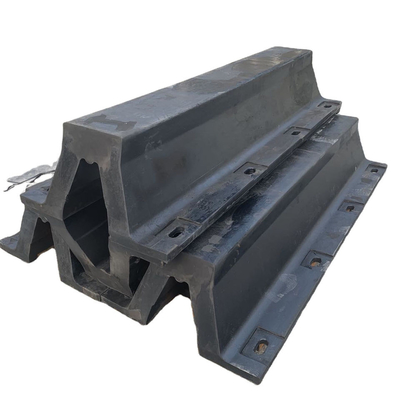

Caratteristiche

Facile installazione e sostituzione

I sistemi di montaggio modulare consentono una rapida installazione o sostituzione senza modifiche importanti del posto di attracco.

Adattabilità a posti fermi o galleggianti

Adatto per basi navali, cantieri navali, piattaforme offshore e banchine galleggianti.

Set di resistenza alla compressione

Mantenere la forma e la capacità di assorbimento di energia anche dopo prolungati carichi statici da sottomarini ormeggiati.

Miglioramento della sicurezza delle attrezzature sensibili

Protegge dalle collisioni i sonar, i periscopi e gli strumenti di ricerca montati all'esterno.

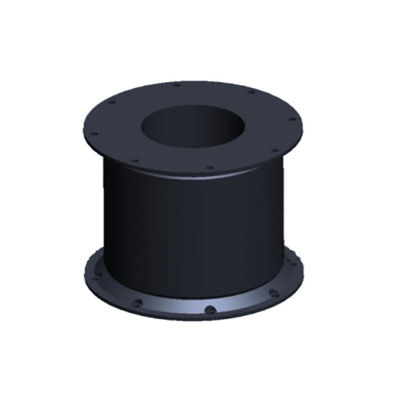

Applicazioni

Operazioni di salvataggio su sottomarini

Impiegato in missioni di salvataggio per attenuare il contatto tra i sottomarini di salvataggio (DSRV) e i sottomarini disabilitati, garantendo un attracco sicuro per il trasferimento dell'equipaggio.

Installazioni militari sottomarine

Proteggere le basi sottomarine segrete, i sistemi di sonar o le penne sottomarine da impatti accidentali durante le operazioni segrete.

Servizi di manutenzione di sottomarini a terra galleggianti

Utilizzato in banchine a secco e cantieri navali per assorbire gli impatti quando i sottomarini sono posizionati per riparazioni, ristrutturazioni o manutenzione.

Vantaggi

Opzioni di celle di gomma riempite di schiuma

Produciamo entrambi i parafanghi sottomarini a schiuma e a celle vuote per soddisfare le esigenze di ormeggio fisso, galleggiante o offshore.

Produzione rapida

La grande capacità produttiva ci permette di soddisfare ordini di grandi dimensioni e necessità urgenti di sostituzione senza compromettere la qualità.

Team di supporto tecnico esperto

I nostri ingegneri forniscono assistenza tecnica completa, dalla consulenza di progettazione alla guida all'installazione in loco.

Meno manutenzione, lunga durata

I nostri parafanghi sono progettati per 15+ anni di utilizzo operativo con manutenzione minima, riducendo i costi del ciclo di vita.

Domande frequenti

1D: Qual è la durata tipica dei vostri parafanghi sottomarini?

R: Con una corretta manutenzione, i nostri parafanghi possono durare oltre 15 anni in condizioni marine normali.

2D: I vostri paraurti soddisfano gli standard internazionali?

R: Sì, sono conformi alle linee guida PIANC, ISO e ASTM per le prestazioni e la sicurezza dei parafanghi marini.

3D: I vostri parafanghi sottomarini sono adatti sia per posti fissi che per posti galleggianti?

R: Assolutamente. Produciamo modelli per pareti fisse, banchine galleggianti e strutture offshore.

4. Q: Come si assicura la qualità del prodotto?

R: Prima della consegna, ogni parafango viene sottoposto a ispezione delle materie prime, controlli dimensionali, prove di trazione e compressione e simulazione delle prestazioni su larga scala.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!