Marine Fenders Superior Protection Excellent Energy Absorption Long Service Life

Description

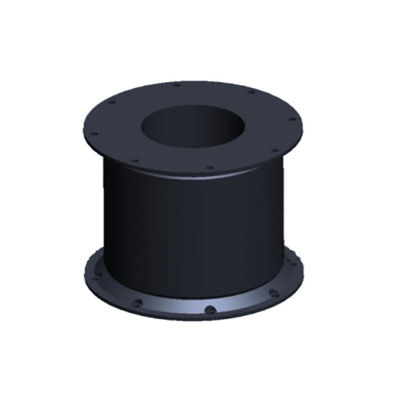

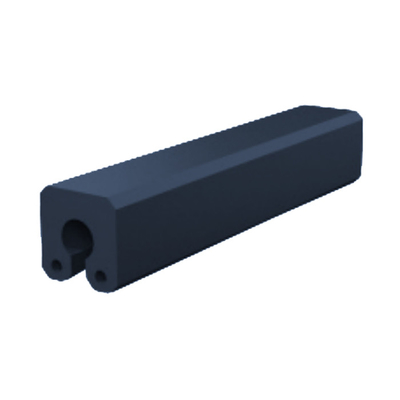

Cylindrical marine fenders represent the pinnacle of marine engineering, designed to provide superior protection for both vessels and port infrastructure. These robust fenders feature a unique cylindrical geometry that ensures optimal energy distribution and maximum impact absorption during berthing operations. Manufactured using advanced elastomer compounds and reinforced with high-tensile steel cords, they deliver exceptional performance in the most challenging marine environments, from tropical ports to arctic terminals. Their versatile design makes them suitable for various applications, including container terminals, bulk carrier berths, and offshore installations.

Case Study: Port of Rotterdam Container Terminal Upgrade

The recent upgrade at Port of Rotterdam's Europa Container Terminal demonstrates the exceptional performance of cylindrical marine fenders in real-world conditions. Facing increasing vessel sizes and higher berthing energies, the terminal replaced its aging fender system with custom-engineered cylindrical fenders in 2022.

Over an 18-month monitoring period, the new fender system successfully handled over 3,000 vessel calls, including the latest generation of container ships exceeding 400 meters in length. The fenders demonstrated consistent energy absorption capacity of 2,800 kN·m while maintaining reaction forces below the terminal's structural limits. Terminal operators reported a 45% reduction in maintenance incidents and eliminated vessel damage during berthing operations.

The installation featured specially formulated rubber compounds resistant to the North Sea's harsh conditions, with performance data showing less than 5% degradation in energy absorption capacity despite constant exposure to saltwater, UV radiation, and temperature variations. The success of this project has set a new standard for port protection systems in major European harbors.

Specifications

| Product Name |

Cylindrical Marine Fenders |

| Material |

Natural Rubber, NBR, EPDM |

| Standard |

PIANC2002, HGT2866-2016 |

| Size |

ID: 75-1000mm; OD: 150-2000mm or Customized |

| Color |

Red, Yellow, Blue, Black, White etc |

| Hardness |

55 Shore A |

| Processing Service |

Moulding, Cutting |

| Tensile Strength |

≥18 MPA |

| Elongation at break |

≥400% |

| Feature |

Environmentally Friendly |

| Application |

Dock, Port, Quay, Boat |

| Advantage |

High Resilience |

| Quality |

Long Lasting Life |

| Function |

Shock Absorption |

| Service |

CustomOEM ODM Service |

| Packaging |

Inner Packing: A. Separate, Each Piece with a Care Label + Tarpaulin

B. Batch, Each Piece is packed in a Transparent Plastic Film

Outer Packing: Tarpaulin or Plastic Film

|

| Model |

Length |

Inside Diameter |

Outside Diameter |

| Cylindrical |

[mm] |

[mm] |

[mm] |

| HM-CMF150 |

Customized Length |

75 |

150 |

| HM-CMF200 |

100 |

200 |

| HM-CMF250 |

125 |

250 |

| HM-CMF300 |

150 |

300 |

| HM-CMF400 |

200 |

400 |

| HM-CMF500 |

250 |

500 |

| HM-CMF600 |

300 |

600 |

| HM-CMF700 |

350 |

700 |

| HM-CMF800 |

400 |

800 |

| HM-CMF900 |

450 |

900 |

| HM-CMF1000 |

500 |

1000 |

| HM-CMF1100 |

550 |

1100 |

| HM-CMF1200 |

600 |

1200 |

| HM-CMF1400 |

700 |

1400 |

| HM-CMF1600 |

800 |

1600 |

| HM-CMF700 |

850 |

1700 |

| HM-CMF800 |

900 |

1800 |

| HM-CMF1900 |

950 |

1900 |

| HM-CMF2000 |

1000 |

2000 |

Features

Advanced Elasticity and Energy Absorption

Cylindrical fenders are engineered with multi-layer elastomer composites, enabling them to absorb and dissipate kinetic energy efficiently. The inner reinforcement layers, typically comprising high-tensile steel cords, work synergistically with the outer rubber shell to minimize reaction forces during vessel impact. This design ensures up to 70% energy absorption, reducing stress on both the vessel hull and berthing structure.

Abrasion and Environmental Resistance

The outer rubber layer is formulated with anti-aging additives and UV stabilizers, providing exceptional resistance to saltwater corrosion, ozone, and mechanical wear. In accelerated weathering tests, these fenders retained 95% of their tensile strength after 10,000 hours of exposure, making them suitable for tropical and polar climates alike.

Low Maintenance and Long Service Life

Unlike pneumatic or foam-filled fenders, cylindrical fenders require no internal pressure checks or complex upkeep. Their monolithic structure eliminates joints or seams prone to failure, reducing lifecycle costs by 30% compared to hybrid fender systems.

Customizable Dimensions and Load Capacity

Available in diameters ranging from 300 mm to 3,000 mm, these fenders can be tailored to specific energy absorption needs (150–3,500 kN·m). Customization options include tailored mounting hardware and surface finishes for specialized applications like LNG terminals or naval bases.

Applications

Container Terminals

Designed to handle high-energy impacts from mega-vessels, cylindrical fenders are installed at hubs like the Port of Rotterdam. Their progressive compression behavior ensures smooth deceleration of ships exceeding 200,000 DWT.

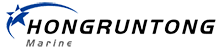

Bulk Carrier Berths

In coal and ore terminals, these fenders withstand abrasive dust and heavy lateral loads. The integration of wear plates on the fender face further enhances durability against rough vessel surfaces.

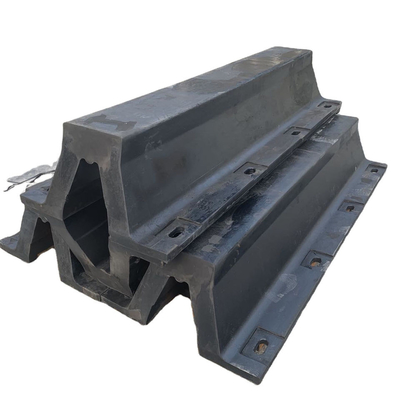

Ro Ro and Ferry Terminals

The fenders’ cylindrical shape facilitates easy roll-on/roll-off operations, providing consistent contact surfaces for vessels with varying freeboards.

Why Choose Hongruntong Marine

Three-Decade Engineering Legacy

With 30 years of specialization in marine fender systems, Hongruntong combines material science expertise with real-world operational insights. Our in-house R&D team collaborates with global port authorities to refine fender designs for evolving maritime demands.

Certified Manufacturing Excellence

All fenders comply with ISO 9001, ISO 14001, and PIANC standards. Our factory utilizes automated vulcanization presses and finite element analysis (FEA) to validate performance under simulated berthing scenarios.

Global Project Support

From design to installation, we provide end-to-end solutions, including on-site technical surveys and dynamic modeling. Recent projects include fender systems for the Panama Canal expansion and offshore wind farm installations.

Sustainable Material Innovation

Our proprietary rubber compounds incorporate recycled polymers without compromising performance, aligning with green port initiatives. Independent audits confirm a 25% reduction in carbon footprint compared to industry averages.

FAQ

1. How do cylindrical fenders compare to cell fenders in energy absorption?

Cylindrical fenders offer more uniform stress distribution, whereas cell fenders excel in high-energy, low-compression scenarios. The choice depends on berthing velocity and vessel displacement.

2. What is the typical lead time for custom diameters?

Custom orders require 8–10 weeks, including material sourcing, vulcanization, and quality testing.

3. Can these fenders be retrofitted to existing dolphin structures?

Yes, mounting hardware can be adapted to legacy systems, though a structural assessment is recommended to verify load compatibility.

4. Do you provide anti-UV treatments for tropical deployments?

Standard fenders include UV-resistant compounds, but additional protective coatings are available for extreme solar exposure.

5. What documentation accompanies each shipment?

Each delivery includes material certificates, installation manuals, and FEA reports upon request.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!