I bitte di ormeggio Hongruntong Marine sono componenti di ormeggio progettati appositamente per cantieri navali, bacini di carenaggio e strutture di costruzione navale, dove sono essenziali un posizionamento preciso, carichi controllati e ampi margini di sicurezza. A differenza dell'ormeggio portuale standard, le operazioni in cantiere navale spesso comportano percorsi di carico non standard, condizioni di ormeggio temporanee e frequenti regolazioni durante le fasi di costruzione, varo e riparazione delle navi. Questi requisiti richiedono bitte con affidabilità strutturale superiore e flessibilità operativa.

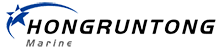

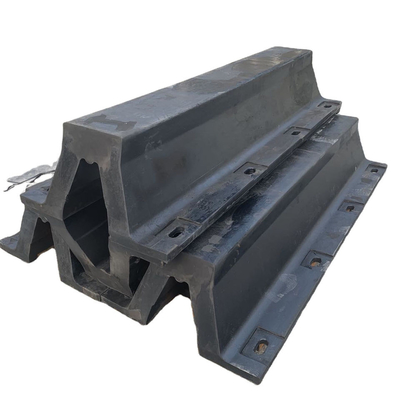

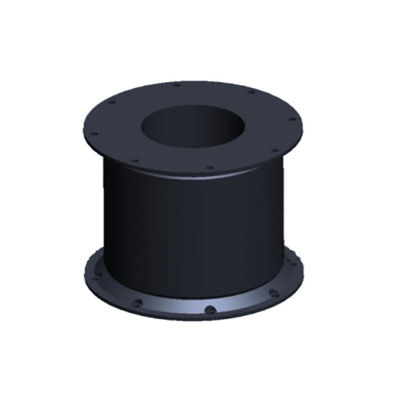

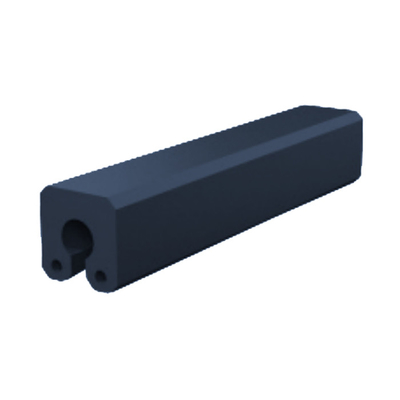

Hongruntong Marine offre bitte di ormeggio con capacità nominali da 50KN a 2000KN, prodotte principalmente in acciaio fuso ad alta resistenza o ghisa duttile. Le bitte presentano una solida struttura di fusione in un unico pezzo che garantisce una distribuzione uniforme delle sollecitazioni ed elimina i punti deboli comunemente associati ai gruppi saldati. Il profilo attentamente progettato consente un aggancio fluido della fune e un trasferimento controllato della forza, riducendo i carichi d'urto durante il movimento della nave.

Con un'eccellente resistenza all'usura meccanica, alla corrosione e all'affaticamento a lungo termine, queste bitte offrono prestazioni affidabili in tutte le fasi della costruzione e della manutenzione navale. La loro durata, adattabilità e prestazioni di sicurezza le rendono una soluzione affidabile per i moderni cantieri navali e le strutture di bacino di carenaggio in tutto il mondo.

Caso di studio – Sistema di ormeggio per bacino di carenaggio di cantiere navale

Un grande cantiere navale commerciale specializzato nella costruzione e revisione di petroliere e navi da carico alla rinfusa (40.000–120.000 DWT) necessitava di un aggiornamento del suo sistema di ormeggio per bacino di carenaggio. Le bitte esistenti erano in servizio da decenni e mostravano segni di usura superficiale e ridotta affidabilità del carico, in particolare durante le operazioni di attracco e disattracco.

Hongruntong Marine ha fornito una serie di bitte di ormeggio in acciaio fuso da 1000KN e 1400KN su misura per l'uso in bacino di carenaggio. Le bitte sono state installate lungo le pareti del bacino e i blocchi di chiglia, fornendo punti di ormeggio sicuri durante l'ingresso, il posizionamento e la manutenzione della nave. È stata prestata particolare attenzione alla geometria di contatto con la fune per garantire la compatibilità con le cime di ormeggio sia sintetiche che in filo metallico comunemente utilizzate nelle operazioni di cantiere navale.

A seguito dell'installazione, il cantiere navale ha segnalato un migliore controllo durante le procedure di attracco, tempi di regolazione ridotti e maggiore sicurezza per il personale del bacino. Su più cicli di attracco, le bitte hanno dimostrato prestazioni stabili senza deformazioni strutturali. Il successo di questo progetto ha portato all'adozione delle bitte Hongruntong Marine come dotazione standard per i futuri aggiornamenti del bacino di carenaggio all'interno della struttura.

Specifiche

| Nome del prodotto |

Bitte di ormeggio |

| Marchio |

Hongruntong Marine |

| Materiale |

Acciaio al carbonio, acciaio inossidabile, lega, ghisa duttile |

| Colore |

Nero e requisiti dei clienti |

| Forma |

Tee, Corno, Pilastro, ecc. |

| Standard |

ISO 13797:2020, PIANC2002 |

| Trattamento superficiale |

Spruzzatura galvanizzante |

| Applicazione |

Porto, Banchina, Molo, ecc. |

Caratteristiche del prodotto

Design strutturale orientato alla precisione

Le bitte sono progettate per fornire un comportamento del carico stabile e prevedibile, fondamentale durante le fasi di posizionamento e costruzione della nave. Le sezioni del collo rinforzate e i percorsi di carico ottimizzati riducono la concentrazione delle sollecitazioni e migliorano la sicurezza generale durante le operazioni di ormeggio controllate.

Materiali ad alta resistenza per ambienti di costruzione

Prodotte in acciaio fuso o ghisa duttile di alta qualità, le bitte offrono un'elevata resistenza alla trazione, un'eccellente resistenza agli urti e forti prestazioni di affaticamento. Queste proprietà sono essenziali nei cantieri navali dove sono comuni urti accidentali, carichi irregolari e configurazioni di ormeggio temporanee.

Superfici di contatto con la fune lisce e durevoli

Tutte le aree di contatto con la fune sono lavorate e sagomate con precisione per ridurre al minimo l'abrasione e l'usura localizzata sulle cime di ormeggio. Questa caratteristica prolunga la durata utile della fune e riduce il rischio di improvvisi cedimenti della fune durante le operazioni critiche.

Adattabilità all'infrastruttura del cantiere navale

Le bitte possono essere installate su pareti di banchina in cemento armato, strutture in acciaio o fondazioni incorporate. Il loro design di base adattabile consente l'integrazione sia in nuovi progetti di costruzione di cantieri navali che nella ristrutturazione di strutture esistenti.

Applicazioni

Costruzione navale e costruzione di navi

Utilizzato durante l'assemblaggio dello scafo, l'allestimento e il varo per fissare le navi in modo sicuro nelle varie fasi di costruzione.

Bacini di carenaggio e cantieri di riparazione

Fornisce un ormeggio stabile durante le operazioni di attracco, manutenzione e riparazione in cui è richiesto un posizionamento preciso della nave.

Aree di varo e messa in servizio

Supporta il movimento controllato della nave durante il varo e la preparazione delle prove in mare, riducendo il rischio operativo.

Perché scegliere Hongruntong Marine

Profonda comprensione delle operazioni di cantiere navale

Hongruntong Marine ha una vasta esperienza di lavoro con i cantieri navali e comprende le sfide uniche degli ambienti di costruzione e bacino di carenaggio.

Personalizzazione basata sull'ingegneria

Le bitte possono essere personalizzate in termini di capacità, geometria e configurazione di montaggio per soddisfare le specifiche esigenze di layout e operative del cantiere navale.

Prestazioni affidabili su lunghi cicli di servizio

Progettate per un uso ripetuto per lunghi periodi, le bitte mantengono prestazioni costanti durante molteplici cicli di costruzione e riparazione.

Forte supporto tecnico e post-vendita

Disegni dettagliati, guida all'installazione e assistenza tecnica continua garantiscono una corretta implementazione e un'affidabilità a lungo termine.

FAQ

1. Queste bitte sono adatte per l'ormeggio temporaneo durante la costruzione?

Sì, sono progettate per gestire sia le condizioni di ormeggio permanenti che temporanee che si trovano comunemente nei cantieri navali.

2. Le bitte possono ospitare sia funi in filo metallico che sintetiche?

Sì, il design di contatto con la fune è compatibile con vari tipi di funi utilizzate nelle operazioni di cantiere navale.

3. Le bitte per cantieri navali richiedono fattori di sicurezza più elevati?

Le applicazioni in cantiere navale spesso comportano carichi non standard e margini di sicurezza più elevati possono essere incorporati nel design.

4. È possibile riutilizzare le fondazioni esistenti del bacino di carenaggio?

In molti casi, le fondazioni esistenti possono essere riutilizzate dopo la valutazione strutturale e il rinforzo, se necessario.

5. Vengono forniti documenti di ispezione e certificazione?

Sì, sono disponibili certificati completi dei materiali, registri di ispezione e documentazione sulla qualità.

Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!  Il tuo messaggio deve contenere da 20 a 3000 caratteri!

Il tuo messaggio deve contenere da 20 a 3000 caratteri! Si prega di controllare la tua email!

Si prega di controllare la tua email!